Flir Qmatic -

Inspection Tool

Year

2023

Duration

10 Weeks

Client

Flir

University

Umeå Institute of Design

Flir Qmatic is a subscription-based Quality Control system designed with a modular and upgradeable architecture, allowing companies to efficiently evaluate the quality of metallic parts. By eliminating the need for ownership and on-site storage, the system removes common logistical and financial barriers. This makes high-precision quality inspection more accessible to a broader range of users, including small manufacturing units, industrial operations, and independent contractors.

Team: Gerardo Soler

Defects Matter

Defects Matter

80% of mechanical failures start with defects

80% of mechanical failures start with defects

Save Big

Save Big

Early inspection can save up to 100× repair costs

Early inspection can save up to 100× repair costs

Market Opportunity

Market Opportunity

Global inspection market projected at $28B by 2030

Global inspection market projected at $28B by 2030

Defects in vehicle assembly can be reduced by up to 80% with effective quality control, leading to increase productivity and major cost savings.

Defects in vehicle assembly can be reduced by up to 80% with effective quality control, leading to increase productivity and major cost savings.

A lot of tools

A lot of tools

While inspection is critical for maintaining quality, the process is often slow and resource intensive. On average, inspections can consume up to 25 to 30 percent of total production time. The reliance on multiple specialized tools, each requiring weeks of training, means only a small fraction of professionals within a company can operate them effectively. This bottleneck increases labor costs by as much as 20 percent and slows down assembly, directly impacting overall efficiency and throughput.

While inspection is critical for maintaining quality, the process is often slow and resource intensive. On average, inspections can consume up to 25 to 30 percent of total production time. The reliance on multiple specialized tools, each requiring weeks of training, means only a small fraction of professionals within a company can operate them effectively. This bottleneck increases labor costs by as much as 20 percent and slows down assembly, directly impacting overall efficiency and throughput.

Useabilty and Interaction

Useabilty and Interaction

To address inefficiencies, we focused on three key tools used most often during inspections: welding quality, material resistance, and coating thickness. These were brought together into a modular device with a digital component. The modular approach combines multiple functions in one system, reducing dependence on specialized tools, lowering training demands, and making inspections faster and easier to manage.

To address inefficiencies, we focused on three key tools used most often during inspections: welding quality, material resistance, and coating thickness. These were brought together into a modular device with a digital component. The modular approach combines multiple functions in one system, reducing dependence on specialized tools, lowering training demands, and making inspections faster and easier to manage.

Efortless Inspection

Efortless Inspection

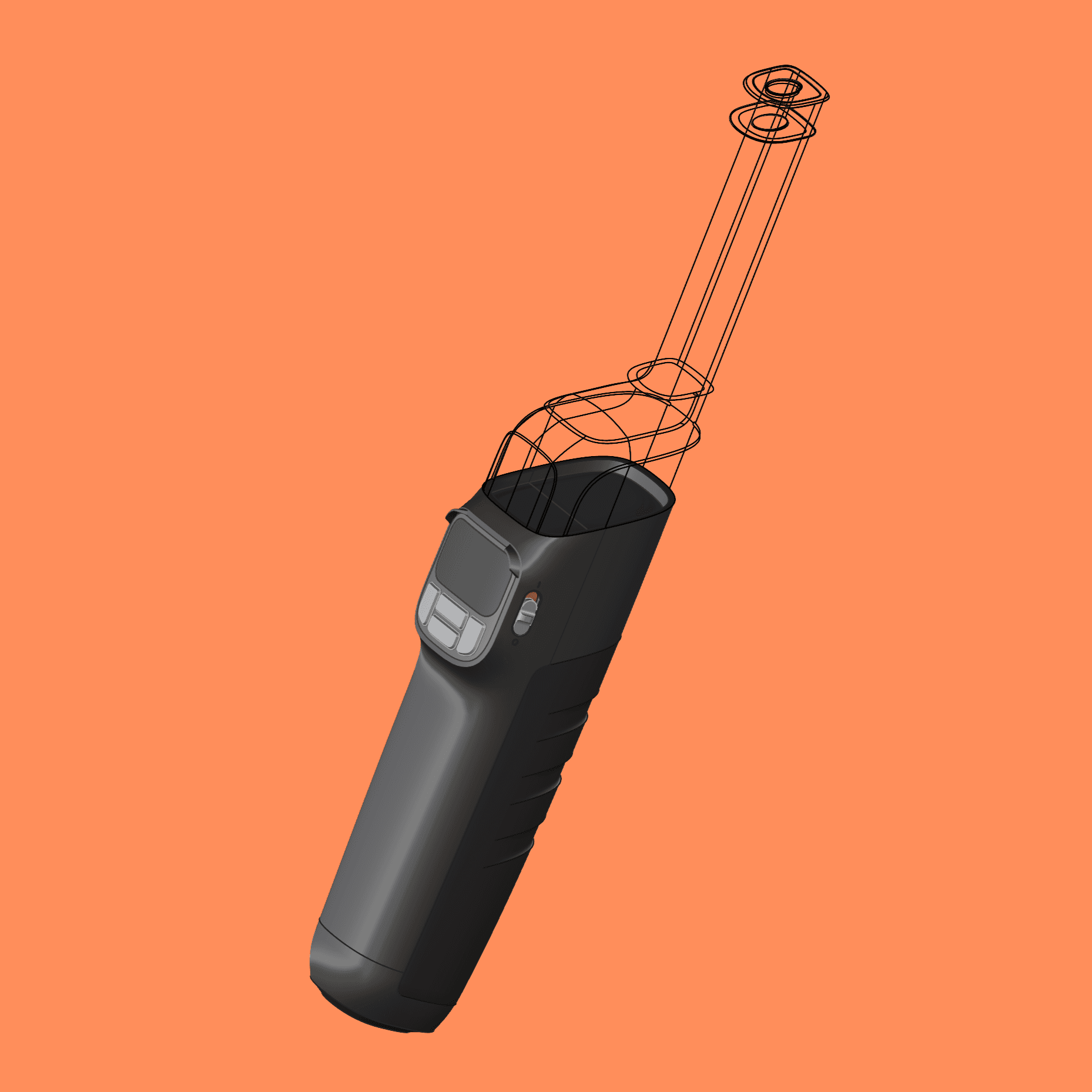

The Flir Qmatic is a user-friendly handheld device designed to assess the quality of parts with precision. The Qmatic Kit includes a main remote and three essential modules that cover key aspects of quality inspection. By combining these features, it enables quality control officers to work more efficiently, streamlining inspections and improving overall productivity.

The Flir Qmatic is a user-friendly handheld device designed to assess the quality of parts with precision. The Qmatic Kit includes a main remote and three essential modules that cover key aspects of quality inspection. By combining these features, it enables quality control officers to work more efficiently, streamlining inspections and improving overall productivity.

The Flir Qmatic is a user-friendly handheld device designed to assess the quality of parts with precision. The Qmatic Kit includes a main remote and three essential modules that cover key aspects of quality inspection. By combining these features, it enables quality control officers to work more efficiently, streamlining inspections and improving overall productivity.

(A) Welding Quality

(A) Welding Quality

(B) Coating thickness

(B) Coating thickness

(C) Material resistance

(C) Material resistance

AORA / Research / NICU Ward

AORA / Interviewing Johannes / the 4th secret team member

AORA / NICU Workspace

AORA / Simulating tubes & Cables / Process

AORA / Concept phase / Form Finding

AORA / Building 1:1 Prototype

The Man / The Myth / The Legend

AORA / Contact points / Cable managemnet

APD gang in Bilbao 2025

PROCESS

SLIDR / Interviewing Truck inspection police

SLIDR / Ideation workshop

SLIDR / 3D scanning Mattias for scale modelling

SLIDR / Filming the underside

SLIDR / Remote 1:1 prototype

SLIDR / Research / Current workspace

SLIDR / Final presentation day

SLIDR / Testing archetypes

SLIDR / in its prime ;)

JODANA / Interviewing Users

JODANA / Context visualisation

JODANA / Process

JODANA / Sketch Video

JODANA / Presentation day with Electrolux

After presentation

PROCESS

QMATIC/ Some cool gear from Flir

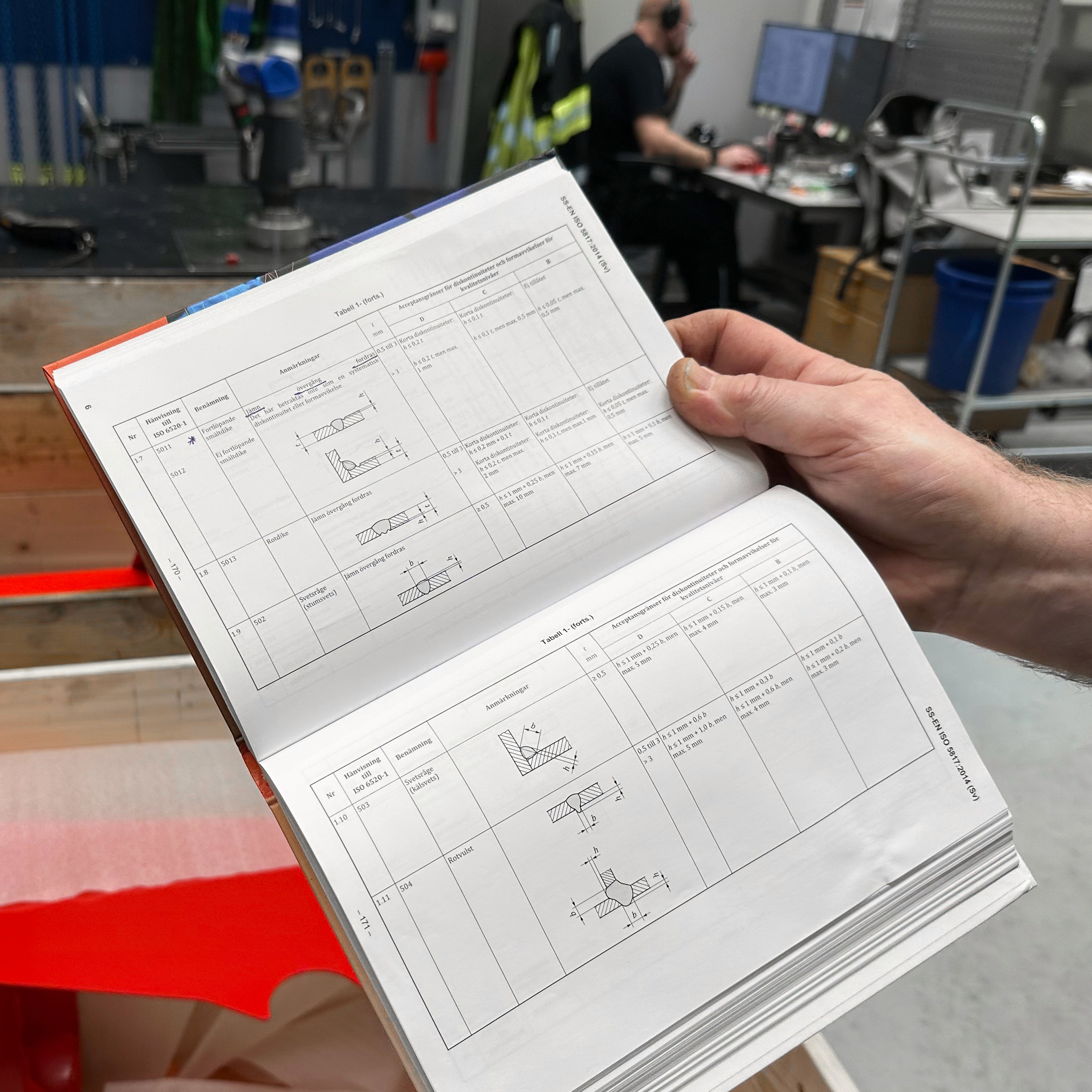

QMATIC / The welding guidance book

QMATIC / Traditional inspection practice

QMATIC / some recent CAD development

QMATIC / Form validation

QMATIC / Testing Prototypes

ALLIE / Late night sanding prototypes

ALLIE / Process / CMF variations

ALLIE / Process

ALLIE / Process / Prototyping

Last day before presentation / 4th attempt

Allie / Process / Filming day

Flir Qmatic -

Inspection Tool

Year

2023

Duration

10 Weeks

Client

Flir

University

Umeå Institute of Design

Flir Qmatic is a subscription-based Quality Control system designed with a modular and upgradeable architecture, allowing companies to efficiently evaluate the quality of metallic parts. By eliminating the need for ownership and on-site storage, the system removes common logistical and financial barriers. This makes high-precision quality inspection more accessible to a broader range of users, including small manufacturing units, industrial operations, and independent contractors.

Yash Saboo

Menu